Our Office

Our passion for our work has grown year by year, to the point that for us, mechanical engineering is now the heart and soul of everything.

Who we are

Studio A.S.E. S.r.l is a technical and mechanical design office, which provides support for manufacturing companies in the design and industrialization of plants and machines, and in drafting the necessary technical documentation for the market release of the finished product.

By providing support and backup for our customers’ in-house technical offices, we enable them to achieve a dual goal:

- responding to production peaks without increasing employee numbers;

- obtaining specialist services for special activities and/or new product development.

Our uninterrupted presence on the market over the past 30 years has enabled us to build up a wealth of experience in a wide range of technical fields.

The highly varied nature of our experience is one of our firm’s strengths, because solutions and functions applied and tested in specific areas can be extended to other applications, thus guaranteeing the safety of the solutions used while at the same time reducing costs. We support manufacturing companies in the design and industrialization of automations, industrial plants, and machines in general, as well as in drafting the necessary technical documentation for their commercialization.

By closely monitoring new technological developments, introducing new software and continuously updating our existing software, we are ideally placed to offer:

- three-dimensional solid modeling services

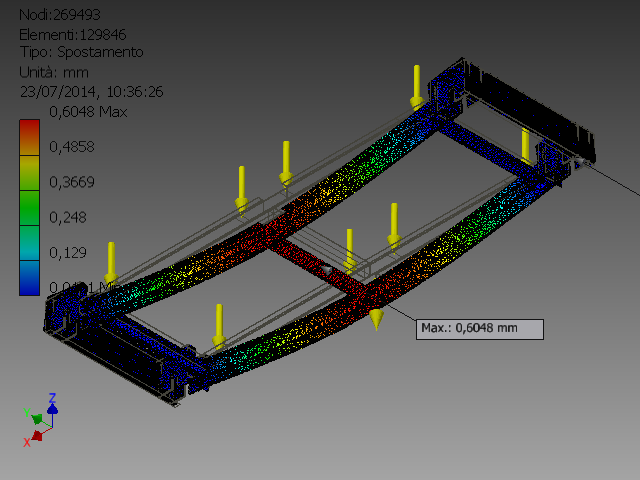

- finite element analysis and kinematic analysis

- dynamic simulation

- drawings of parts and exploded views

- cost analysis

- project management

- supplier search and support

- construction of prototypes and pre-series

- reverse engineering

- consulting on the Machinery Directive

- photo-realistic rendering

- product presentation brochures

A specific team of professional technicians produces models for die-castings, shell-mold castings and injection molds.

Our history

Studio A.S.E. S.r.l. was established in 1988, when its founder, Athos Sorghini, with the help of his wife Graziella, decided to take a new career direction and devote his energies to mechanical design, for which he had always had a passion.

The newly formed company was made up of a few professional technicians, who used a drafting machine and rolls of paper to produce their technical drawings.

Over the years, technological advances, combined with the use of two-dimensional and three-dimensional design software and an increasing wealth of experience in new sectors, enabled our firm to grow and increase its staff numbers considerably, by taking on highly professional technicians.

On the strength of their ability and the passion they inherited from their father, the founder’s sons, Erick and Denis, started working alongside their parents in running the firm a few years ago.

In response to our need for new workspaces, conference rooms and a modern work environment, we extended our headquarters in 2018

Method and Project Management

Preliminary analysis and feasibility study

After first contact with a potential customer, every proposed activity is screened and analyzed by the appropriate Project Manager.

On the basis of a general guideline, an initial analysis is conducted to highlight the key characteristics of the project in order to identify the points that require the most input or a preliminary analysis of possible alternatives.

On completion of this first phase, which can also involve the designated designer, we draw up a quote to give the customer an idea of the investment required. The quote specifies the time schedule for the work, deadlines, software to be used (unless expressly requested by the customer) and the proposed cost.

Once the quote has been accepted, the designated manager opens an internal job order, to which all information, examples and other input from the customer is saved.

Design: the crucial phase of every project

The design process cannot proceed without a job order from which to start and from which to extract all the concepts and characteristics needed to do the job. It is vitally important, for the entire project life-cycle, to build the right basis of information from the outset.

To complete our customers’ projects on time, we always adhere to a specific series of operating phases:

- Plan: the project does not start until the preliminary phase has been completed. In agreement with the customer, the designer starts from an overall study in order to gain a full insight into the critical points that emerge in the preliminary phase.

- Do: the project takes shape, at study level, as the designer produces solutions that solve the critical points previously identified. In the case of substantial or urgent projects, the designated designer can be backed up by colleagues who support him by progressing with other points of the project in parallel. On completion of the study phase, we move onto part number allocation (on the basis provided by the customer) and the realization of ballooned sub-units and parts for production.

- Check: the initial phase involves constant liaison between the designer and manager, so as to ensure that no aspects of the project are neglected. Contact with the customer is equally crucial, as the latter needs to make certain key choices that arise in the course of the work.

- Act: the critical aspects of a project are often interconnected. In such cases, decisions that offer advantages in one respect can cause disadvantages in another. It is essential to consider the project as a whole, in order to find the best overall solution. It may therefore be necessary to take a few steps backwards, when a change in approach is clearly needed.

You have a dedicated team, so you always know who to contact

In addition to the manager tasked with overseeing the project at all times, every project has a main designer fully dedicated to it.

Depending on the scale and urgency of the project, the main designer can be temporarily or continuously backed up by other colleagues as necessary.

The customer can interface with the manager and designated designers at all times, in a range of ways, including the use of desktop sharing software.

Thanks to the powerful telecommunications infrastructure, a VPN can be used to connect directly to the customer’s database to speed up the procedures of part number allocation and entry of the outputs.

When necessary, the designer can visit the customer’s site to facilitate the execution of the work.

Staying on schedule: the secret of success

The activity is specifically managed in such a way as to deliver the graphical outputs as requested by the customer.

Unexpected problems sometimes emerge during the course of the project, which require more time than was initially forecast.

The manager is responsible for promptly notifying the customer of any obvious differences with respect to the estimated schedule and taking action to increase the resources assigned to the project in order to adhere to the agreed delivery date.

Industrial sectors we operate in

Over the years, we have gained extensive experience in numerous manufacturing sectors and undertaken projects in a wide range of fields, including automation, systems engineering, product handling and the food, automotive and HVAC industries.

HVAC and plumbing industry

Design and development of domestic and industrial heating systems.

Discover our projects in this sector.

Confectionery industry

Design and development of machines and plants for the bakery sector.

Discover our case studies.

Food industry

Design and development of pasta production lines, design and development of ovens, mixers and filling machines.

Discover our projects.

Packaging industry

Design of packaging and “end-of-line” machines, machines for packaging loose products for the food, pharmaceutical and cosmetics industries.

Discover our projects.

Automotive industry

Design and development of internal combustion engines and test benches.

Transport industry

Design and development of port installations, road construction machinery and conglomerate production machinery.

Discover our projects.

Software used

Expertise and knowledge of the major 2D and 3D design software, so that all projects can be managed and completed to customer requirements.