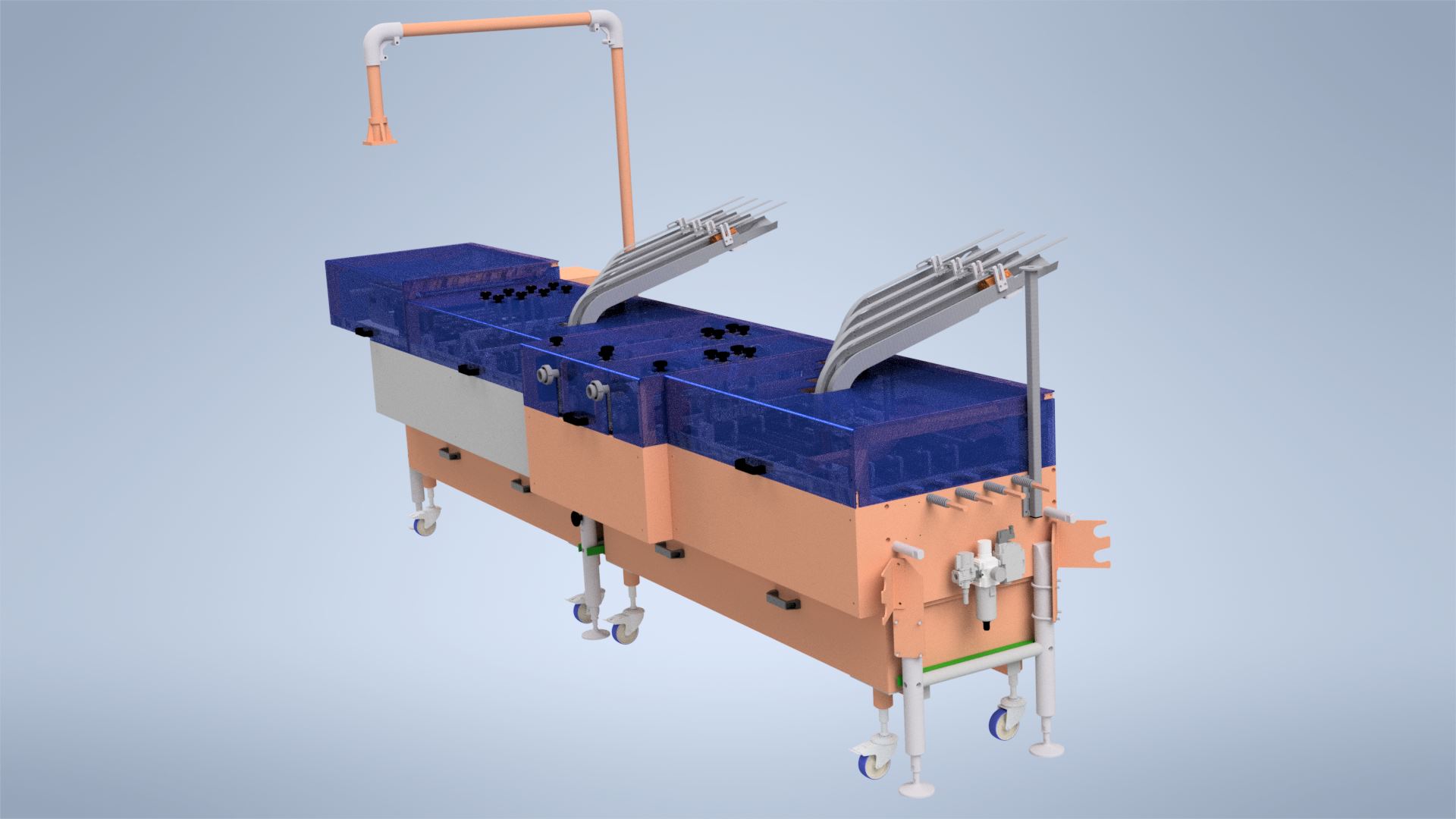

Mechanical design of a biscuit production line

Our technical design office designed a biscuit production line for a confectionery company. The machine is designed to overlay the biscuits in line in four rows.

The aim was to design a machine capable of performing various operations in a single process: e.g. rotating the biscuit by means of a turning system, overlaying the biscuits in line in four rows, transferring the biscuits fed out of the sandwich machine to the multiplier and dividing the biscuits fed out of the transfer system into 8 rows.

A machine with these capabilities doubles production capacity, thanks to the design of multiple "outfeeds" for the biscuits produced.

We developed the design assembly by assembly in such a way as to allow the operation of the individual machine.

The plant consists of the following machines:

- Newly designed 4-track SANDWICH machine, whose function is to overlay the biscuits in line in four rows. For the purposes of its mechanical design we developed:

- a system for transferring the biscuits in channels, guided by adjustable side panels;

- a new concept for pushing the biscuits, involving two lateral rings of chain and a cross-piece with pushing function;

- a new biscuit reject system;

- a new stencil

- new movable covers.

- Newly designed 4-track TRANSFER SYSTEM for transferring the biscuits from the Sandwich machine to the Multiplier, whose function is to transfer the biscuits fed out of the sandwich machine to the multiplier. The basic concept is the same as for the sandwich machine, and involves a drive system comprising two lateral chains connected by cross-pieces. The motor is mechanically coupled with the sandwich machine motor.

- Newly designed row MULTIPLIER from 4 rows to 16 tracks; this machine’s function is to divided the biscuits fed out of the transfer system into 8 rows. Our design does not feature pegs on each transfer plate, but instead involves the application of a gripping film that keeps the biscuit stable on the work surface. This solution makes it possible to dispense with the unloading device (star) located at the outlet and therefore to unload the product onto the downstream conveyor more easily.