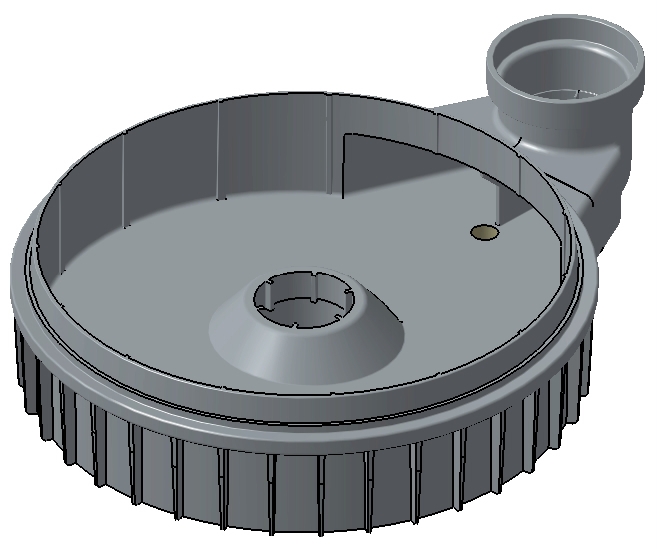

Condensing boiler base

Studio A.S.E. realized the solid modeling of an highly efficient condensing boiler bottom plate.

For this project, instead of vinyl resin, we choose polypropylene as the moulding material.

We focused mostly on:

- reducing thicknesses: going from a general thickness of 5 mm to one of 3 mm

- respecting geometries, to ensure a large degree of interchangeability of the piece.

The project was accompanied by deformation tests, in order to optimize the number of ribs on the piece so to avoid deformations due to high temperatures.